Only a proven procedure guarantees you a solvent distiller suitable for your needs.

Our professional approach involves a proven procedure based on the complete collection of information before proposing any commercial solution.

The goal is to fully understand the specific operational issues and dynamics of the company.

This phase can take place through telephone communications or, preferably, with a direct visit to the company itself.

We pay particular attention to this aspect because, especially in Italy, where we are known for our “artistic” skills in addressing problems, planning is a fundamental element for the success of the project.

I am convinced that anyone making an investment needs certainty and not improvisations based on unforeseen circumstances.

Have you ever bought something and felt like you were venturing into the unknown, without any guarantee? Expecting one result and then getting something different?

Consider what this entails in economic terms and stress, making an investment to solve a problem and discovering that it has created others.

It’s not your fault, we are well aware of that, because unfortunately things work this way.

Once you have paid, you stop being a customer and the problems become yours to manage.

We, on the other hand, are committed to providing you with a proven procedure, based on a thorough understanding of your situation and your goals.

I can offer you the guarantee that our approach is based on solid planning and solutions that meet your specific needs.

Contact us to discuss your needs for managing the waste solvent generated by your production process.

You will discover how the proven procedure can guarantee you the desired result, avoiding uncertainties and unforeseen events that often occur during investments for solvent distillers.

And what if it were possible to prevent these inconveniences?

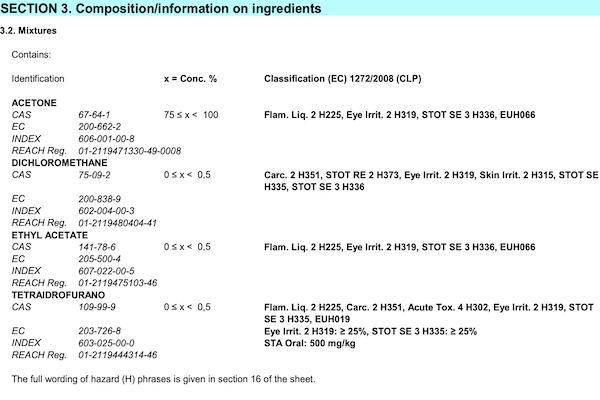

I want to share with you a real case of a customer who needed to recover perchloroethylene contaminated by oils, greases, and metal dust in emulsion, resulting from the final phase of the industrial parts machining process.

The goal was to recover 1,000 liters of dirty solvent per day, to reuse it in production, with as little human intervention as possible to monitor the distillation process.

We are aware that operators should spend their time on more profitable activities than simply monitoring a machine to manage operational details.

During the case analysis, a possible problem emerged related to the scraper blades of the distiller, due to the metal dust in emulsion present in the dirty solvent to be treated.

For this reason, we thought it appropriate to perform a distillation test using the contaminated solvent supplied by the customer.

Here are the results of the test:

After conducting a thorough analysis and evaluating all aspects emerged from the distillation test, we are able to provide you with a specific offer that takes into account the type of solvent, distillation times, quantity to be distilled, operational needs, and available budget.

We want to emphasize that our working procedure is based on three fundamental phases:

- Collection of detailed information from the customer.

- Execution of targeted distillation tests to exclude any doubts or problems.

- Presentation of a specific technical-commercial proposal.

It is important to understand that I cannot simply offer you a solvent distiller without knowing all the specific details of your case.

Our approach is not limited to providing estimates and selling products. First of all, we carry out a complete analysis of the context to identify possible criticalities and areas to be improved. Subsequently, we verify the identified solutions, often involving the technical office.

If a solution is not feasible or does not guarantee optimal operation, we prefer to stop and find the correct approach. There is no “let’s go ahead and see” approach.

We are committed to ensuring that you get a safe and reliable solution to your problem, avoiding creating further complications.

We also do not neglect those factors that may seem marginal in the distillation process, but that actually significantly affect the final results and your satisfaction.

Your trust and the effective resolution of your problem are our absolute priority.

Why is the number of customers who rely on us constantly increasing?

The main reason for this continued success lies in the methodical approach and based on concrete data. Our working procedure is not limited to verbal promises but provides a tangible guarantee for the entire project.

When it comes to your investments, you can choose to rely on someone who advises you a certain approach just because “it has always been done this way”, or you can opt for someone who guarantees you results based on concrete evidence obtained through specific tests conducted on your materials.

It’s a bit like relying on an experienced surgeon who plans his intervention based on thorough analysis and a careful preparatory phase.

Our constant attention to quality and commitment to ensuring concrete results are the reasons why more and more customers choose to rely on us for projects related to the distillation of contaminated solvents.

In addition to the performance guarantee, it is important to underline that Ciemme stands out as the only distillation equipment manufacturer to offer its customers an amazing warranty on its products as well. This warranty can extend for up to five years for the most significant and crucial machines, showcasing our commitment to ensuring the highest reliability and satisfaction for those who choose our equipment.