Can a solvent distiller be dangerous?

Reports of accidents, fires, explosions, and tragedies involving workers in companies, sometimes with very serious consequences, raise concerns about safety even in the context of solvent distillation activities. It is important to emphasize that a solvent distiller, in itself, is not dangerous. However, under certain circumstances, it can pose a risk that should be avoided.

Let’s examine the situations in which a solvent distillation unit could become dangerous.

– Lack of maintenance is certainly a critical factor. A distiller requires regular maintenance to ensure proper functioning, efficiency, and safety. It is useful to take care of the regular replacement of the diathermic oil, the safety valve, and the oil cap.

– Improper use or non-compliance with the manufacturer’s guidelines can cause accidents, such as the leakage of flammable liquids or vapors

– Design or manufacturing issues also play a role: a poor-quality solvent distillation unit can represent a risk and become dangerous over time. It is essential to choose reliable manufacturers and ensure that the solvent distiller complies with safety standards and current regulations.

– The area where the distiller is placed is equally important. It must be a well-ventilated area and comply with safety standards for flammable liquids. Improper solvent management can increase risks: it is essential to follow safety procedures in their handling.

Regarding ATEX classification, it is important to carefully evaluate the location of the solvent reclaimer. We have seen distillers suitable for non-classified areas placed in ATEX zones, where solvents and paints are stored. In this case, the problem is not the solvent reclaimer itself, but the error in placement. We advise against purchasing non-ATEX certified systems for installation in classified areas. It is important that such machines are preferably placed outside, in ventilated environments.

When operating in a classified area, it is crucial to evaluate the area classification and choose an ATEX-certified distiller for zone 1 (ATEX II 2G). Before purchasing a distiller, planning the placement carefully is fundamental. In case of uncertainty, always opt for an ATEX-classified machine.

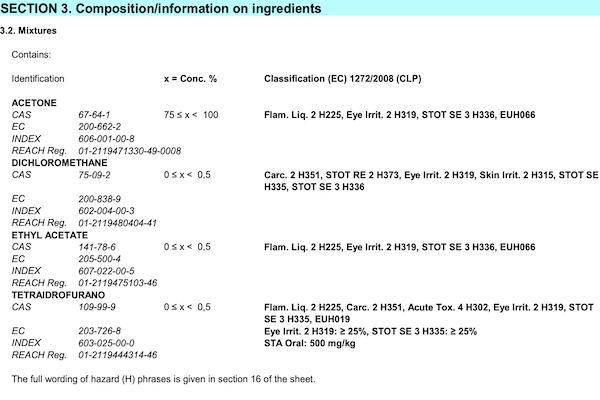

– It is also important to be aware that some solvents are not suitable for distillation. Substances containing nitrogen, such as nitromethane, nitroaromatics, and nitrates, can react dangerously. Only solvents with an auto-ignition temperature above 250 °C should be distilled. Special attention is required for nitrocellulose, often used in paints and inks. During the distillation of solvents contaminated with nitrocellulose, it is important not to exceed 120 °C, avoid drying out the residue, which favors auto-ignition, and discharge the residues at each cycle.

– Finally, operator training is fundamental for safety. This must include knowledge of the characteristics of solvents, their reactions, and associated hazards. Safety information is available on Safety Data Sheets (SDS) provided by solvent suppliers. It is also important to take precautions against electrostatic charges, verifying the electrical system and ensuring that the operator and the plant are properly grounded.

In conclusion, the choice of a solvents reclaimer should not be based solely on price. It is essential to be aware of the regulations and safety measures to follow. In the past, safety awareness was not so widespread and often the enforcement of laws was less strict. However, today things have changed, and decisions cannot be taken superficially. It is essential to carefully evaluate the machine, the certifications it possesses, and the reliability of the supplier. Investing in safety and compliance with current regulations is a crucial step to avoid unpleasant situations and protect the company and its staff.

Ciemme, to ensure the safety and efficiency of your solvent distillation unit, is able to provide you with a planned maintenance schedule. Thanks to this preventive strategy, you can work safely and enjoy consistent and long-lasting performance. This approach not only reduces the risk of sudden failures but also helps to prolong the life of your solvent reclaimer, allowing you to maximize the yield and effectiveness of your investment.

With our planned maintenance schedule, we commit to providing you with a comprehensive service at advantageous conditions that ensures the continuity and reliability of your distiller.