Solvent distillation for inks: benefits, tips, and analysis

Printing is a fundamental element of packaging, requiring the use of significant quantities of inks, often containing solvents. But what happens to these ink solvents once they are used? Are they destined for disposal, or can they be distilled and reused?

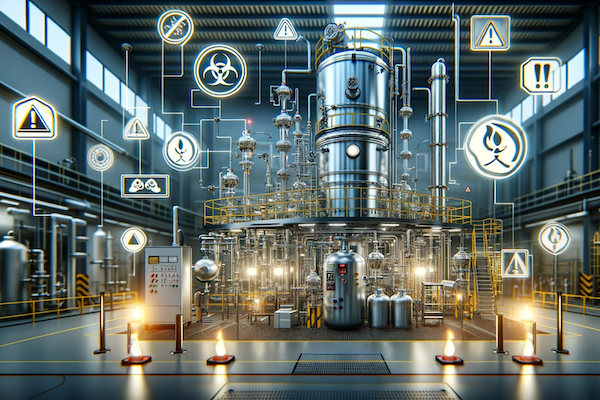

The distillation of ink solvents is an increasingly common practice to streamline consumption and reduce environmental impact. Distillation enables the recovery of solvents used in printing and machine cleaning, making them available again for the production process.

But is distilling ink solvents truly advantageous? How is the process carried out, and what technologies are available? What are the advantages and disadvantages of this practice?

To answer these questions and more, we will guide you through a comprehensive analysis of ink solvent distillation. You will discover the secrets to proper solvent management and optimizing your production process, thereby reducing costs and environmental impact.

If you’re a company focused on environmental awareness and sustainability, don’t miss the opportunity to learn how ink solvent distillation can contribute to your success.

Gravure and flexographic printing require the use of solvent-based inks, which can incur high costs for solvent purchasing and disposal. But what happens if these solvents are recycled within the company?

Distillation for solvent-based inks represents a sustainable cost-saving opportunity for graphic companies. Instead of accumulating and disposing of solvents as special waste, they can be reused for machine cleaning.

Before delving deeper into this topic, it’s important to understand what a “solvent” is. A solvent is a liquid capable of dissolving a solid, liquid, or gaseous solute, forming a solution. Practically, the solvent is the main component of a solution, defining its concentration and solubility.

Solvents are commonly used as components of inks and for cleaning printing machines. However, their use also entails the need to purchase, manage, and dispose of them correctly. But is there an alternative?

Our company specializes in designing and manufacturing solvent distillers for graphic companies, reducing solvent purchases and disposal costs. Specifically, we focus on nitrocellulose-based inks commonly used in gravure and flexographic printing.

Solvent recycling not only presents a cost-saving opportunity for companies but also a sustainable practice appreciated by customers seeking ecologically conscious suppliers.

Recovering solvents used for cleaning and washing printing machines can be an excellent choice from both an economic and environmental perspective. But how can you avoid risks and achieve optimal results? First and foremost, it’s crucial to adhere to some basic rules, such as preventing nitrocellulose from becoming dry or almost dry, being cautious of high concentrations of acidic and/or alkaline components, and not treating solvents at temperatures above 120°C, using vacuum distillation. Additionally, maintaining a clean tank is essential to prevent decomposition and overheating of deposits, and not letting distillation residues dry excessively.

But what are the advantages of distilling exhausted solvents instead of disposing of them?

First and foremost, economic savings: 1 liter of distilled solvent costs about one twentieth of a new product. Furthermore, operability is generally straightforward, especially with automatic or semi-automatic distillers.

Additionally, you won’t be tied to your solvent supplier’s supply times and conditions, as you’ll only purchase a minimal amount of the product, freeing yourself from price increases as seen in recent years.

The amount of solvent stored in the company will significantly decrease, as you won’t have the inventory of exhausted solvent (to be disposed of), thereby reducing fire risks.

If you’re looking to recover exhausted solvents in your company, distillation is an economical, ecological, and safe solution. However, choosing and using the correct distiller is essential to ensure the success of the operation and the safety of operators.

Here are some tips to assist you in choosing and using the distiller:

- Verify that the distiller is suitable for treating solvents containing nitrocellulose and is Atex certified by an accredited third-party organization to ensure operator safety.

- Carefully assess your needs in terms of material quantity to be treated, timing, and type of operation, to choose the most suitable distiller.

- Controls must be managed by personnel who are not only trained in operation but also in the risks related to managing nitrocellulose-containing residues, paying attention to the product to be distilled.

- The distiller should work for several years, so it’s important for it to be both effective and reliable.

Seguendo questi consigli, potrai scegliere il distillatore giusto per le tue esigenze e ottenere i migliori risultati.

By following these tips, you can choose the right distiller for your needs and achieve the best results.

Distillation of exhausted solvents can be done manually, semi-automatically, or automatically. The cycle consists of three phases: solvent loading, heating and distillate discharge, and residue discharge. The choice of the type of system depends on the needs of the user company in terms of material quantity to be treated, timing, and type of operation.

It’s important to emphasize that, according to industrial safety regulations, the responsibility for treating by products and disposing of waste falls entirely on the user (printer). The ink and solvent supplier only provide safety data sheets containing the necessary information for the proper use of the products by personnel.

Furthermore, the ROI of a distiller is advantageous. It’s thus an effective investment to reduce production management costs and increase profit margins. Choose the best solution for distilling your exhausted solvents and ensure the safety of your operators and work environment. Contact us for more information about our Atex certified distillation systems.